Art teachers use them to turn students’ drawings into three-dimensional objects; agriculture educators use them to show how farm irrigation works; physics teachers use them to build robotic arms; and special education teachers use them as an incentive for their students.

When the Nucor Detailing Center in Norfolk, Nebraska partnered with five local school districts to introduce junior high students to 3D printing, it anticipated MakerGear printers would be used a great deal in technology-related classes. What surprised them was the many other innovative uses of the machines.

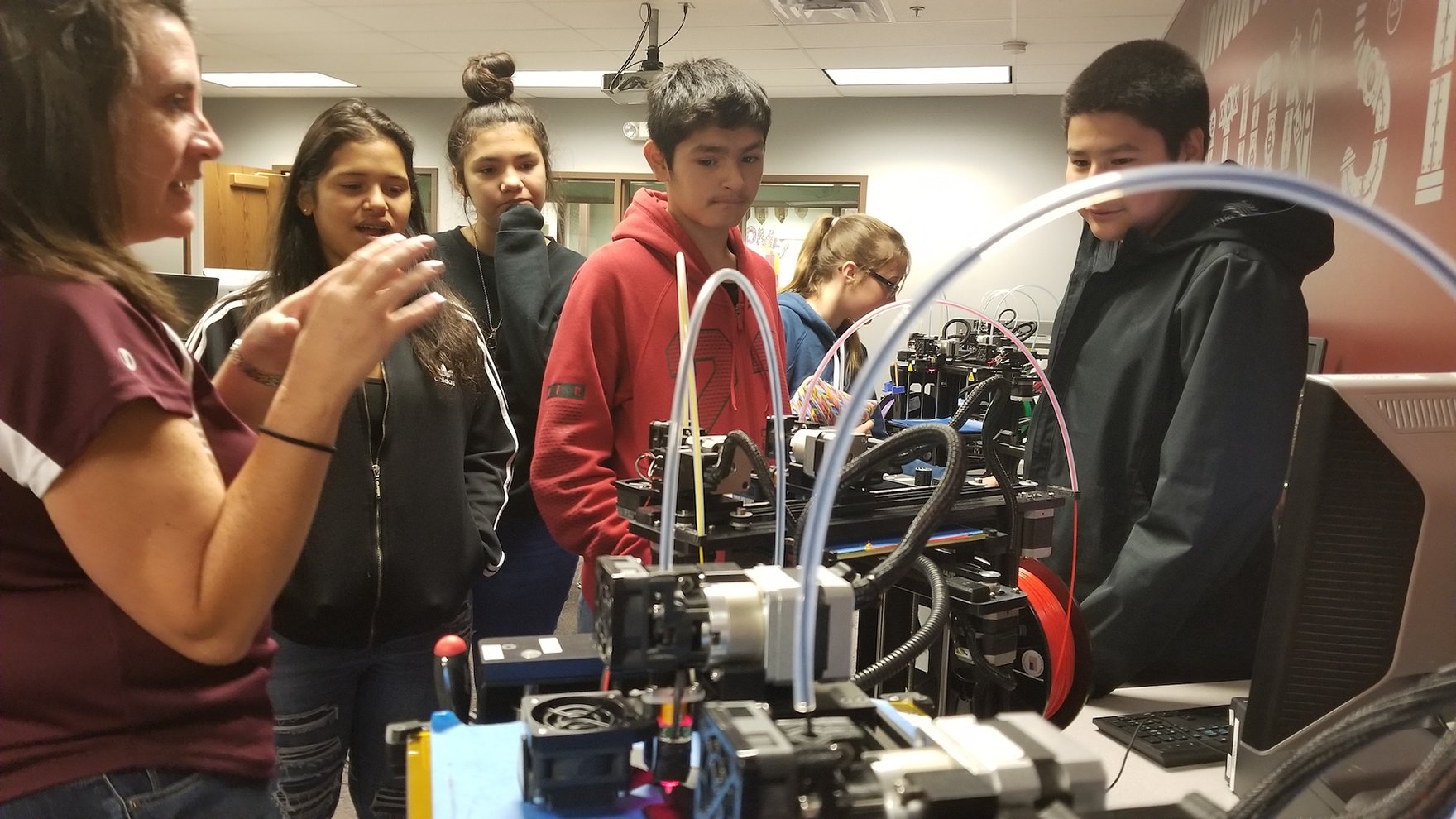

“3D printing is an easy way to generate excitement with students in many grade levels and varying interests,” says David DeCarolis, a trainer with Nucor. “The sound and movement of the printers spur the interest and curiosity of the kids. Once they are focused on 3D printing, it becomes easier to have discussions about additive manufacturing and careers that use this technology.”

Nucor is the largest steel products manufacturer in the United States with over 25,000 employees across 300 locations. The company teamed up with the school districts to create a program that promotes interest in manufacturing, engineering and technology careers among 7th and 8th grade students.

Together, Nucor and the school districts received a $125,000 grant, which provided the schools with age-appropriate manufacturing equipment, including eleven MakerGear M3-ID printers, laser engravers, CNC machines, vinyl cutters, and embroidery machines. These “Creation Stations” include a permanent makerspace at Norfolk Junior High School and a mobile makerspace to provide equipment to four other rural schools.

The program also features training for teachers and presentations for students by Nucor staff to ensure both the educators and kids know how to properly use the equipment. As a result, teachers are incorporating 3D printing into their existing curriculum and their students are replicating the design-to-manufacture process that is at the heart of careers with Nucor.

“The goal of the program is to introduce junior high students to drafting and manufacturing career skills,” DeCarolis says. “The long-term goal is to strengthen the future manufacturing, IT and drafting workforce in Northeast Nebraska.”

Due to class sizes, schools often struggle to find enough time to allow all students to print their models. The program addresses this issue by providing multiple 3D printers in the Creation Stations.

“With our MakerGear printers and Simplify3D software, we are able to load multiple models, print in two colors simultaneously, and even use the dual extruders to print two identical objects at the same time, which doubles our print speed,” DeCarolis says.

In 2018, the program provided over 1,000 students with access to new technology and learning experiences. Early surveys indicate the program has increased their interest in manufacturing. Nucor and its educational partners are looking for ways not only to sustain but grow the program. They are focused on establishing permanent Creation Stations in the four other rural schools, instead of sharing a single traveling makerspace between them.

Nucor has already provided additional money and the schools have sourced funds to purchase additional hardware. Principals and teachers have said that once district administrators saw the students enthusiastically engaged with the equipment, especially the 3D printers, it was easy to convince them of the value that the makerspaces bring to their school.